|

Press Release

MK Pump Company expands operations to improve stripper oil well performance through micro-pumping.

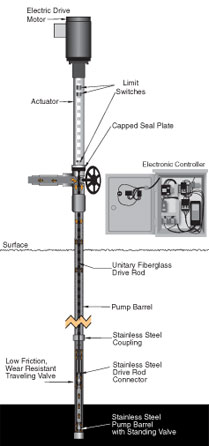

MK's tough, lightweight, economical one-package system recovers oil gently, reliably without overpumping the formation Next-generation technology works like pump jack systems, but units are smaller and less than half the cost to operate and purchase MK Pump Company announced it is expanding operations in U.S. and global oil production markets, aiming its next-generation oil pumping products at improving the productivity of stripper wells. "Our reliable and affordable product line helps stripper-well operators pump more oil and less water by gently sipping the oil without disturbing the column we call it micro-pumping," the company said. "Our technology is based on the reliable pump jack system, but we have successfully miniaturized and updated the concept to make it easier and more economical to recover shallow oil." "MK's system is proven and efficient, with operating and purchase costs less than half of traditional pump jack systems. We have an incredibly small footprint in the field, and at less than 125 pounds, our patented pumps can be installed, operated and maintained quickly and easily. Of course our products are compatible with standard oil well heads" the company said. "We really do give new life to stripper wells." Pumping products include MK's Rhino MiniJack™ top-head-drive, positive displacement piston pump, built to perform across a wide range of low-flow micro-pumping environments. The Rhino MiniJack can be fine-tuned to the oil yield of a formation reducing water intake, gas lock and emulsification. The Rhino MiniJack electric pump recovers oil reliably at controlled rates of up to 15 bbl/day at 1,500 feet. Pump components, including motor size, traveling valves, rods, connectors and downhole components, can be matched to individual pumping situations. The electric motor can be made explosion proof. A pneumatic motor option is available. MK Pump also offers the new MK SmartBox™ Controller, which allows well operators to program their pumps to optimize specific pumping situations. Instead of on-off, stop-and-go operations, the SmartBox senses downwell conditions and environmental changes, then adjusts pump dynamics to match well outputs. Advanced software varies stroke counts and running speeds, which eliminates the need for the pump to shut down. The effect of this tightly controlled activity is to boost productivity while reducing the drive's overall speed. Slower speeds mean lower horsepower requirements, resulting in reduced energy costs and less wear on vital pump components. "With the Rhino MiniJack Piston Pump and the SmartBox Controller, MK Pump is uniquely positioned to help stripper operators and the oil industry recover valuable assets that are still within reach," the company said. "Micro-pumping is the next step in efficiently maximizing the potential of the oil patch." MK Pump Company manufactures the only patented top-head-drive piston pump system developed to recover oil easily and economically from stripper wells. Along with its predecessor company, MK Pump has more than 15 years of real-world field experience in developing and improving pumping products in oil fields and petrochemical facilities. MK builds its products to ensure rigorous flow specifications while withstanding the harshest outdoor environments and the most difficult downhole pumping conditions. Please visit www.mkpump.com for more information or call 800.469.4887

Press Releases

For Immediate Release

MK Pump Company expands operations to improve stripper oil well performance through micro-pumping. Read more » For Immediate Release MK Pump Company introduces next-generation high-efficiency, low-cost pump to improve stripper oil-well performance.Read more » |

How It Works

|