|

Here's what makes MK's Rhino MiniJack different

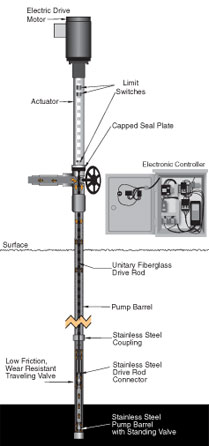

- Field-serviceable top-head-drive motor is mounted just above the pumping unit and the oil being pumped, resulting in extremely dependable, efficient and easy-to-control mechanics, with simple servicing

- State-of-the-art, programmable-logic controller tightly manages pump activity and reduces operating costs, while built-in communications port offers easy off-site computer monitoring

- Weather-resistant actuators are built for extreme conditions

- Unlike bulky heavy iron, the Rhino MiniJack has a remarkably low profile and small footprint

- The Rhino MiniJack is simple to install and easily portable, weighing less than 125 pounds

- Patent-pending stuffing box prevents surface leaking and allows fast surface change-outs

- These positive-displacement pumps provide optimal flow rates and can pump uniformly against high head, independent of the liquid head in the well

- The Rhino MiniJack's downhole pump features a machined, rolled and welded stainless steel pump barrel with standing valve, plus a stainless steel check ball and seat to ensure no-leak performance and long life

- Stainless steel pump barrel stands up to tough chemical, gas, grit and silt environments

- Downhole pump barrels are in broad service, with millions of successful pumping hours

- Made of low-weight, high-strength, low-friction material or brass, depending on downwell temperature and chemistry

- Field proven to provide extended service life

- Low-friction material is ideal for applications requiring resistance to abrasion

- Seals are easily replaced

- Lightweight unitary drive rods have the strength to go deep, yet allow the pump to work more efficiently and economically, with lower horsepower

- MK Rhino MiniJack pumps are adaptable to existing tubing and well heads

- Choose up to 15 bbl/day to depths of 1,500 feet using 3 hp electric motor, or up to 15 bbl/day to depths of 750 feet using 1 hp motor

- Solar and Pneumatic Motor Option

- Unitary fiberglass rod is high strength and low weight, which allow fast installation at low cost

- Continuous drive rod up to 1,500 feet

- Highly reliable reinforced rods run cleanly and easily, and are designed for the most demanding situations, including hot, viscous oil wells

- Explosion-proof electric motor option meets U.S. Class 2, Div. I requirements

- All-weather actuator stands up to extreme hot and cold environments

- Top-head-drive actuator motor is mounted on top of well head, and is fully field-serviceable

- Choose easy-to-use pump time and dwell set-up with external communication port - allowing you to decide speed, time between pumps, and time of day, week or month to pump

- Pre-program speed, hour run time, stroke count, dwell delay time for both up and down stroke, auto restart if electric service interrupted, time-of-day on/off

- Match production with actual well inflow by changing pump cycle time in the well or through continuous altering of pump speed

- Accurately control rod pumping system, determining when pump needs to run to reduce utility costs

- Actuator and control work together to reduce rod load and torque, resulting in lower horsepower requirements

- Built-in communications port allows operator to monitor, manage and optimize Rhino MiniJack pumps from a single, off-site control point

- Pump and controls come ready to plumb and plug in

- Choose a standard unit or mix and match components for individual needs

- Rhino MiniJack top-head-drive motors

- Rhino MiniJack downhole assembly products

- Rhino MiniJack controls

- Rhino MiniJack drive rods

Press Releases

MK Pump Company expands operations to improve stripper oil well performance through micro-pumping. Read more »

MK Pump Company introduces next-generation high-efficiency, low-cost pump to improve stripper oil-well performance.Read more »

Data and Marketing Sheets

|

|